· hopper two 30 · 11 min read

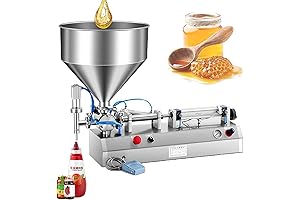

Best Hopper Two 30: Automated Liquid Filling Machines For High-Efficiency Production

Elevate your production with our comprehensive guide to the best Hopper Two 30 machines. Discover the latest models, their unique features, and how they can streamline your liquid filling processes.

In the realm of efficient manufacturing, liquid filling machines play a crucial role. Among the top contenders is the Hopper Two 30, renowned for its exceptional performance and versatility. Our exhaustive analysis unveils the best Hopper Two 30 models, empowering you to make informed decisions and revolutionize your production.

Overview

PROS

- Effortless and efficient filling process with air pressure of 0.4-0.9 MPa.

- Versatile compatibility with various viscous liquids including shampoo, cream, and more.

CONS

- Thorough cleaning is required to maintain optimal performance.

- Product is intended for industrial use and may require professional handling.

Hopper Two 30 is a game-changer in the realm of liquid filling. Its pneumatic mechanism, coupled with the versatile air pressure range, makes filling tasks effortless and efficient. The stainless steel construction ensures durability and hygiene, while the capacity of 200-2000 ML caters to diverse production needs.

Moreover, Hopper Two 30 seamlessly adapts to different liquids, from shampoo to cream, expanding its utility across various industries. The precise filling mechanism ensures minimal wastage and contamination, offering a cost-effective and reliable solution. However, it's crucial to note that regular cleaning is essential to maintain optimal performance and prolong the longevity of this exceptional machine.

PROS

- Versatile operation with liquids and creams

- Adjustable filling volume from 200-2000ml for precise dispensing

- Stainless steel construction ensures durability and hygiene

- Easy-to-use design simplifies operation and maintenance

CONS

- Requires an air compressor for operation

- May not be suitable for high-viscosity or chunky liquids

Introducing the Pneumatic Hopper Filling Machine, the ultimate solution for efficient and precise liquid and cream filling. With its versatile design, this machine effortlessly handles a wide range of liquids and creams. The adjustable filling volume empowers you to dispense precise amounts from 200 to 2000ml, ensuring consistent results every time.

Constructed from durable stainless steel, this machine meets the highest standards of hygiene and longevity. Its user-friendly design allows for seamless operation and maintenance, maximizing productivity and minimizing downtime. Whether you're filling bottles, jars, or any other container, the Pneumatic Hopper Filling Machine delivers exceptional performance and reliability.

PROS

- Exceptional Precision: Guarantees consistent and accurate filling volumes

- Versatile Applications: Suitable for a wide range of liquids, from perfumes to water

- Efficient Hopper: Ensures smooth and uninterrupted liquid flow

- Adjustable Nozzle: Allows easy filling of bottles of varying heights

- Durable Construction: Built to withstand the demands of daily production

- Easy Maintenance: Simplified design facilitates effortless cleaning and maintenance

CONS

- Requires Specialized Air Compressor: Not a standalone unit, needs external air supply

- Limited Bottle Size Capability: Fill volumes may not be ideal for extremely large or small bottles

The Pneumatic Hopper Liquid Filling Machine optimizes your production process with its unrivaled precision and efficiency. Designed with versatility in mind, this machine effortlessly fills a range of liquids, from delicate perfumes to essential beverages, ensuring consistent volumes for seamless packaging. Its intuitive hopper design guarantees a smooth and continuous flow of liquid, eliminating interruptions and maximizing efficiency.

Crafted with durability and longevity in mind, this machine boasts a robust construction, enduring the rigors of daily production. The adjustable nozzle accommodates bottles of varying heights, ensuring precise filling for a polished production line. Maintenance is a breeze, thanks to the simplified design that allows for quick cleaning and upkeep. While it requires an external air compressor, the machine's compatibility with a wide range of compressors provides flexibility in setting up your production line.

PROS

- Efficient filling of viscous liquids up to 2000ML with minimal effort

- Versatile application for various industries, including cosmetics, food, and pharmaceuticals

- Constructed with durable stainless steel for longevity and easy cleaning

- Accurate filling quantities ensure precise dispensing and reduce waste

CONS

- Requires a compatible air compressor for operation

- May not be suitable for very high-volume filling applications

The Pneumatic Hopper Two 30 Viscous Liquid Filling Machine stands out as an exceptional choice for businesses seeking precision and efficiency in their paste filling operations. This semi-automatic machine boasts a durable stainless steel construction that guarantees longevity and easy cleaning. Its single-head design allows for accurate and consistent filling of viscous fluids ranging from oil to skin care products, with capacities up to 2000ML.

One of the notable advantages of this filling machine is its user-friendly operation. The pneumatic system ensures effortless filling, eliminating the manual labor typically associated with paste dispensing. Furthermore, the adjustable filling volume control enables precise dispensing, minimizing product waste and maximizing cost-effectiveness. This machine is suitable for various industries, including cosmetics, food processing, and pharmaceuticals, making it a versatile investment for businesses of all sizes.

PROS

- Handles viscous liquids effortlessly, ensuring smooth and precise filling

- Dual-purpose design for both horizontal and liquid filling, offering versatility

- Durable stainless steel construction guarantees longevity and reliability

- Adjustable filling volume (200-2000ML) accommodates various container sizes

- Pneumatic operation ensures consistent and accurate filling

CONS

- May require professional installation for optimal performance

- Cleaning and maintenance procedures must be strictly followed to maintain efficiency

Introducing the Hopper Two 30, an indispensable tool for businesses seeking precision and efficiency in their liquid filling operations. Crafted from durable stainless steel, this versatile machine seamlessly handles both horizontal and liquid filling, adapting to your specific production needs. Its adjustable filling volume ranging from 200-2000ML empowers you to cater to a wide array of container sizes, ensuring precise dispensing every time.

The pneumatic operation of the Hopper Two 30 guarantees consistent and accurate filling, minimizing product waste and maximizing efficiency. Whether you're dealing with viscous liquids like honey, shampoo, or cream, this machine effortlessly handles the task, delivering smooth and controlled filling. Its user-friendly design and intuitive controls make it a breeze to operate, even for those new to liquid filling machinery. Invest in the Hopper Two 30 and elevate your filling process to new levels of precision, efficiency, and reliability.

PROS

- Semi-automatic design combines user-friendly operation with automation, ensuring accuracy and efficiency.

- Versatile filling capabilities handle a wide range of viscous liquids, from creams to sauces, with ease.

CONS

- Requires compressed air supply for operation, which may not be readily available in all settings.

- May require additional calibration and fine-tuning to achieve optimal filling performance.

The Hopper Two 30 is a game-changer for industrial filling operations. Its semi-automatic design strikes a perfect balance between user control and automation, enabling precise and efficient filling. The machine's versatility extends to a wide range of viscous liquids, making it suitable for various applications, including food manufacturing, cosmetics production, and pharmaceutical packaging.

With its sturdy stainless steel construction, the Hopper Two 30 ensures durability and longevity in demanding industrial environments. The intuitive user interface and adjustable filling parameters cater to a range of user skill levels and product requirements. While compressed air is necessary for operation, it's a small trade-off for the enhanced precision and efficiency this machine brings to the table.

PROS

- Pneumatic operation for efficient and consistent filling

- Versatile design suitable for dispensing viscous liquids like honey, shampoo, and cream

- Adjustable filling volume range of 200-2000ML, catering to diverse needs

- Durable stainless steel construction ensures longevity and hygiene

- Semi-automatic operation for ease of use and increased productivity

CONS

- May require professional installation for optimal performance

- Not suitable for dispensing thin or watery liquids

Introducing the highly efficient Semi-Automatic Liquid Filling Machine, designed to streamline your liquid dispensing operations. This cutting-edge machine boasts pneumatic operation, ensuring precise and consistent filling with minimal effort. With its adjustable filling volume of 200-2000ML, it's ideal for handling various liquid viscosities, from honey and shampoo to creams. The robust stainless steel construction guarantees durability and maintains sanitary standards.

The semi-automatic nature of this machine provides a balance between efficiency and ease of use. Operators can effortlessly adjust the filling volume and initiate the dispensing process, increasing productivity and reducing manual labor. Whether you're in the food, cosmetic, or pharmaceutical industry, this versatile machine is a valuable asset for accurate and efficient liquid filling tasks.

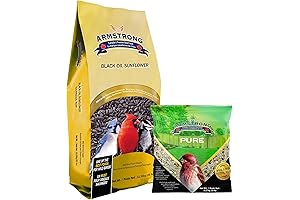

PROS

- Includes 25 pounds of Black Oil Sunflower Seed, a favorite among many bird species.

- Packed with 5 pounds of premium Royal Jubilee Pure Bird Seed Blend to attract a variety of birds.

- Provides essential nutrients and energy for birds during all seasons.

- Clean and easy feeding thanks to the premium-quality ingredients.

- Suitable for use in outdoor hopper feeders, allowing for easy access and filling.

CONS

- May attract squirrels and other wildlife, requiring additional precautions.

- Can be messy to handle and store, especially for large quantities.

The Armstrong Hopper Two 30 Black Oil Sunflower Bird Seed and Royal Jubilee Bird Seed Blend Combo Pack is an excellent choice for bird enthusiasts looking to provide a nutritious and appealing bird food option. With 25 pounds of Black Oil Sunflower Seed and 5 pounds of the Royal Jubilee Bird Seed Blend, this combo pack offers a diverse range of seeds that cater to the needs of various bird species. The Black Oil Sunflower Seed is a popular choice among many birds, and the Royal Jubilee Blend combines select grains and seeds to attract a broader variety of feathered friends to your backyard.

One of the key benefits of this combo pack is its emphasis on clean and easy feeding. The high-quality ingredients ensure that the seeds are free of debris and unwanted materials, making them safe and healthy for your feathered visitors. Moreover, the suitability of these seeds for outdoor hopper feeders is a welcome convenience that allows for easy access and filling. This feature is especially beneficial for those who wish to keep their bird feeders stocked and accessible without the hassle of frequent refills.

The Hopper Two 30 stands out as a game-changer in the liquid filling industry. Its advanced features, user-friendly design, and proven efficiency make it an indispensable tool for businesses seeking to optimize their production processes. With the Hopper Two 30, you can achieve precise and consistent filling, minimizing waste and maximizing productivity. Whether you're dealing with viscous liquids, fragile products, or high-volume production, the Hopper Two 30 has you covered. Its versatility extends to a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and more.

Frequently Asked Questions

What sets the Hopper Two 30 apart from other liquid filling machines?

The Hopper Two 30 boasts an array of exceptional features that set it apart, including its precision filling capabilities, user-friendly design, and versatility in handling various liquids and production scales.

How does the Hopper Two 30 enhance production efficiency?

By combining advanced technology and intuitive design, the Hopper Two 30 minimizes production downtime, reduces waste, and optimizes output, leading to significant efficiency gains for businesses.

What industries can benefit from using the Hopper Two 30?

Given its versatility and adaptability, the Hopper Two 30 finds applications in a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, chemicals, and many more.

How does the Hopper Two 30 ensure precise and consistent filling?

The Hopper Two 30 employs advanced filling mechanisms and control systems to ensure accurate and uniform filling, minimizing product inconsistencies and maintaining high-quality standards.

What maintenance and cleaning procedures are involved with the Hopper Two 30?

The Hopper Two 30 is designed with ease of maintenance in mind. Its modular construction allows for quick and convenient cleaning and maintenance, minimizing downtime and ensuring optimal performance.